The Epoflex® 6N laminate tank lining system is an internal tank lining system to rehabilitate tanks directly on-site without interruption of site service ensuring business continuity. The lining provides a structural contribution to the integrity of the tank which is maintained by the lining in case of external pit corrosion even by the formation of a hole in the steel.

Due to this the structural reinforcement of the tank, the tanks obtain on average more than 15 years of additional life. The liquid epoxy-based coating materials are classified as solvent-free, high solid, non-flammable, and ensuring safe operation at the construction site.

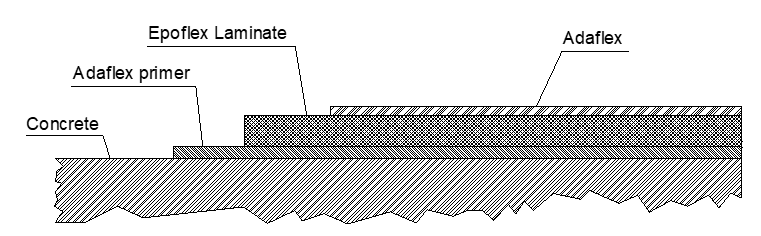

The system can further be applied to concrete due to the crack bridging effect.

Structure of the lining system:

Preliminary Works:

The lining system shall be applied on the degreased and clean surface according to the adhesion criteria of ISO EN 18479 for epoxy-based materials:

- Surface treatment, cleaning, degassing, remove all oil residuals

- Repairing the surface and leveling of weldings with epoxy mortar

Coating Application Technology:

- Manual application of lamination on the surface with ADAFLEX® and application of woven double-layered fiberglass (450 g/m2)

- Coverage of the glass fiber with ADAFLEX® of the laminate

- Slightly rub or sandpaper of the entire surface, remove dust

- Application of EPOFLEX® top layer system by spraying or rolling

- Check for pinholes with pinhole tester and rework possible pinholes

- Application of the conductive/antistatic layer ADAPOX® by rolling

Installation note:

The above information is based on tests by approved institutes (e.g. TÜV Süd Germany) and many years of experience. As the lining performance depends on correct installation, we offer application courses for certified installers and installation supervisors and provide certificates which shall be renewed every 3 years.