Wolftank Austria recently implemented a tank roof lining in Austria.

The scope of the project

Bulk storage tanks in tank farms or refineries are endangered by outside corrosion. These steel tanks face not only with inside corrosion, which is caused by the medium. But with external corrosion as well, which is the result of weather conditions, humidity, salt, etc.

Therefore, an external tank roof lining is an important investment which helps saving the assets (tank and medium) and requires protection against environmental difficulties.

The challenge

Our customer is one of the biggest oil companies in central Europe and definitely the most powerful in Austria. They have high standards of safety and quality, so the biggest challenge was to find a subcontractor who is able to fulfil all these high requirements.

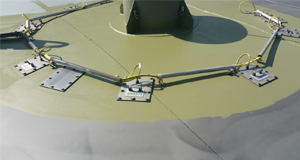

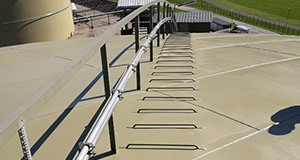

Besides this challenge, there was another one. The application of the roof is very difficult because of its own conical shape. In addition, the team would need to clean the roof subsurface in order to reach the SA2,5 cleanliness.

The solution

As the roof is an uncovered area and to avoid any serious pollution, we had to find a closed cleaning system instead of the regular sand blasting solution.

Our partner used a shot blasting machine which provided the necessary cleanliness and roughness.

The advantages of the shot blasting are:

- 3 times faster and cheaper

- less…

- effect on the working speed and efficacy because of weather conditions

- waste material

- dust and dirt

After achieving the proper subsurface requirements, the application of the corrosion protection system is the next step. As this area is in high corrosivity category (>C4), the system contains three different layers:

- Ground layer

- Intermediate layer

- Top layer

The team applied all the resins with an airless spray unit and, by the difficult approachable spots, they used rollers for spreading.

The outcome

The lining system has 20 years of lifetime and now, the roof tank is completely ready for any adverse environment. Wolftank Austria finished the project before the deadline, while keeping all the safety instructions. Hence, the costumer was satisfied too.

With this challenging tank roof lining Wolftank Austria could expand its reference working list with a customer, which in addition, is a big player on the market. The professionalism was recognised and the company keeps participating on the customer´s tenders with high hit rate.

More information about our lining systems available here.