Wolftank Austria is pleased to announce its latest development: the industrial Hole Sealing Kit for tanks, vessels and pipes.

Wolftank Austria kit is enabling easy and quick hole sealing, allowing to seal corrosion holes in steel tanks, cracks in fibreglass (FRP) and similar small damaged storage containers: effortlessly with a short instruction delivered together with the product.

Premium Wolftank Austria quality

This complete kit relies on exclusive Wolftank Austria products, which make sure the result is of best available quality:

On the one hand, Wolftank Austria’s specially formulated surface preparation solutions TCR® Cleaning Liquid and TCR® Rust Converter make sure the surface receives only the best performing treatment by degreasing and removing heavy rust before applying the epoxy coatings.

On the other hand, high-performance epoxy resins, Epoflex® SK and Laminierharz Epoflex® 6N support the repair layers’ long-lasting integrity.

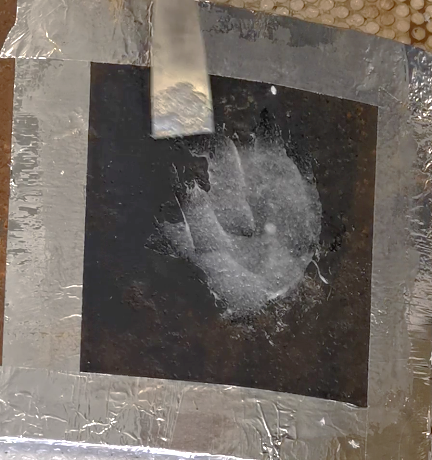

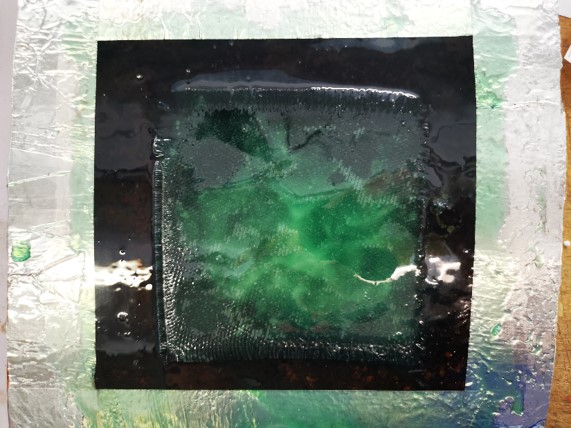

Firstly, Epoflex® SK covers and closes the corrosion with its fast-drying and hardening properties (see Figure 1). Meanwhile, Epoflex® Laminierharz 6N provides the top-layer protection completing the hole sealing operation (see Figure 2).

Additionally, the whole sealing kit contains the following tools completing the circle of a full ready-to-use corrosion hole repair:

| Sandpaper (P40) | Spatula | Steam Roller | Mixing Container | Steel Brush | Fiberglass | Aluminium Tape | Aluminium Sheet |

Flexible use for a broad field of industries

Its design able to resist fuels, chemicals, and industrial water or wastewater allows using it in a wide range of industries, such as agriculture, oil and gas, chemical refineries or storage farms. Its simple yet effective application, non-dangerous components and excellent mechanical properties make it an excellent choice for maintenance services. Enabling quick and effortless action in case of a leaking asset and so quickly prevent further environmental damage.

Undoubtedly, what makes the complete sealing kit special is the fact that it provides the same integrity as hot works. This means that hot works to restore the integrity are not necessary and all the risks coming with them are completely avoided.

The Hole Sealing Kit provides following advantages:

- Resistant to regular fuels, biofuels, chemicals, and waste- or industrial water

- Very easy to apply: no specialized training is necessary

- Allowing quick reaction in case a leakage occurs

- Solvent-free, non-flammable and non-dangerous

- Risk-free hole repair; no hot works

Business continuity while repairing a hole

The industrial Hole Sealing Kit comes in two different types. The first version is for empty containments; the second one is for containments currently containing or transporting liquids, whereas a quick reaction is necessary to stop further environmental pollution or spilled liquids.

- Hole Sealing Kit without spilling liquids

This sealing technology mainly used for containments that do not contain any liquids. For instance, empty storage tanks, water containments, pipes or similar. In this situation, a repair can take place without any countervailing forces pushing through the hole.

- Hole Sealing Kit with spilling liquids

It is a great choice for containments which still contain liquids. As you would expect, these liquids cause a countervailing force exiting through the hole and harden the repair work. This version of the kit can be used in pipes, storage tanks or water containment.

The Hole Sealing Kit with spilling liquids synergizes perfectly with the Wolftank Austria Spill Absorbent Pillows. Easily achieve the most environmentally friendly hole repair work by placing the Absorbent Pillows below the leaking hole while repairing it. These absorbents make sure no liquids reach the ground while the maintenance team can carry out the hole repair.

As an example, the following video briefly explains how to carry out the repairing process with the Hole Repair Kit:

Therefore, get a Hole Sealing Kit now and extend your maintenance service equipment with an easy-to-use hole sealing solution!

More information on the industrial Hole Sealing Kit is available here.

In addition, the detailed manual explaining how to successfully repair leaks can be downloaded here.